“QuickFrames made a difference by alleviating coordination issues relieving the headache of trying to chase down dimensions we need from other subs. They install faster to cut down on time needed for other projects.”

The Leader in Engineered Structural Roof Frames

QuickFrames free up fabrication and detailing saving time, budget and labor.

65,000+ Frames Installed

Across U.S. and Canada

85% Faster

Up to 85% Faster to Install than Welded Angle Iron

24 – 48 hour Quotes

Ships to Jobsite

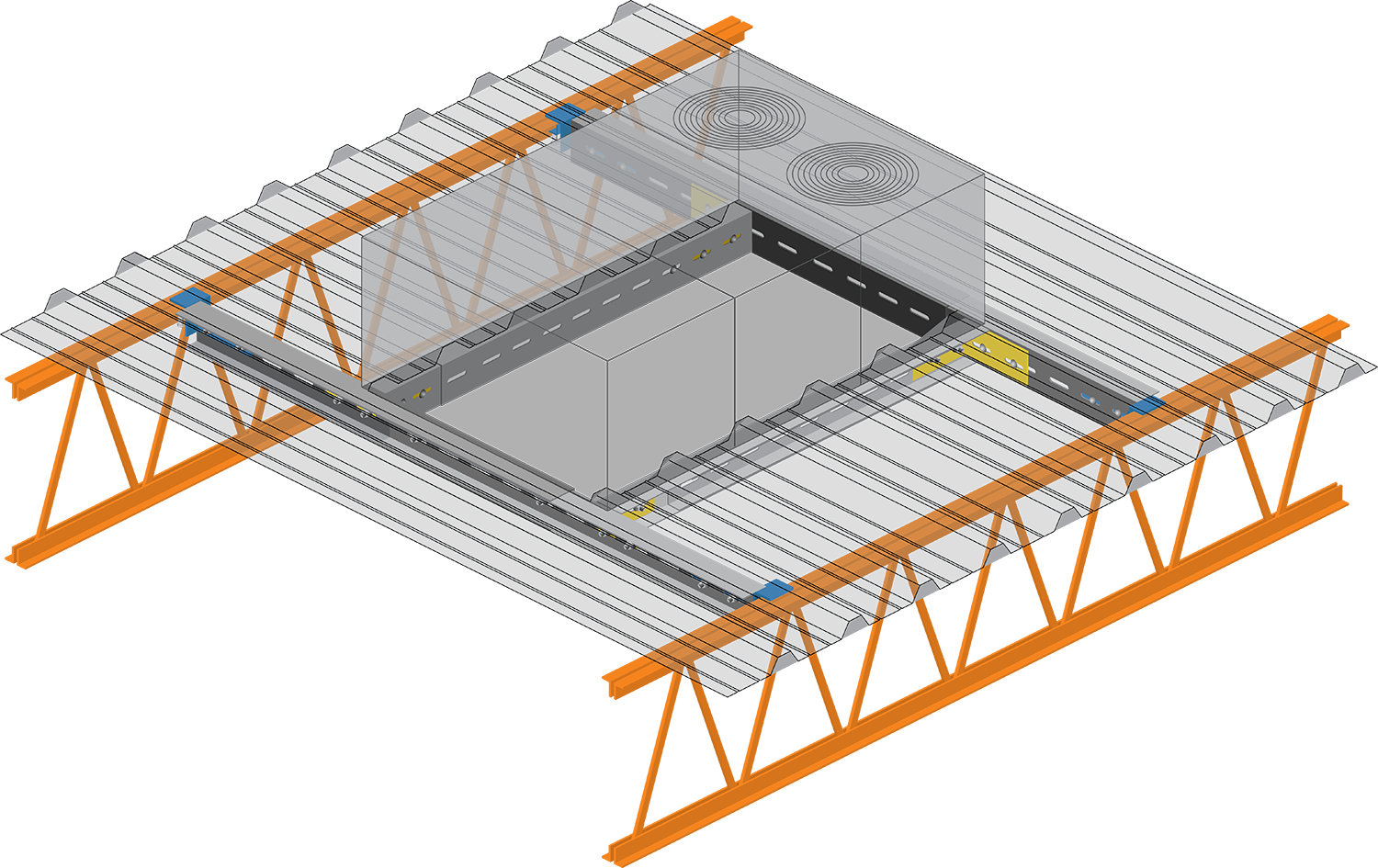

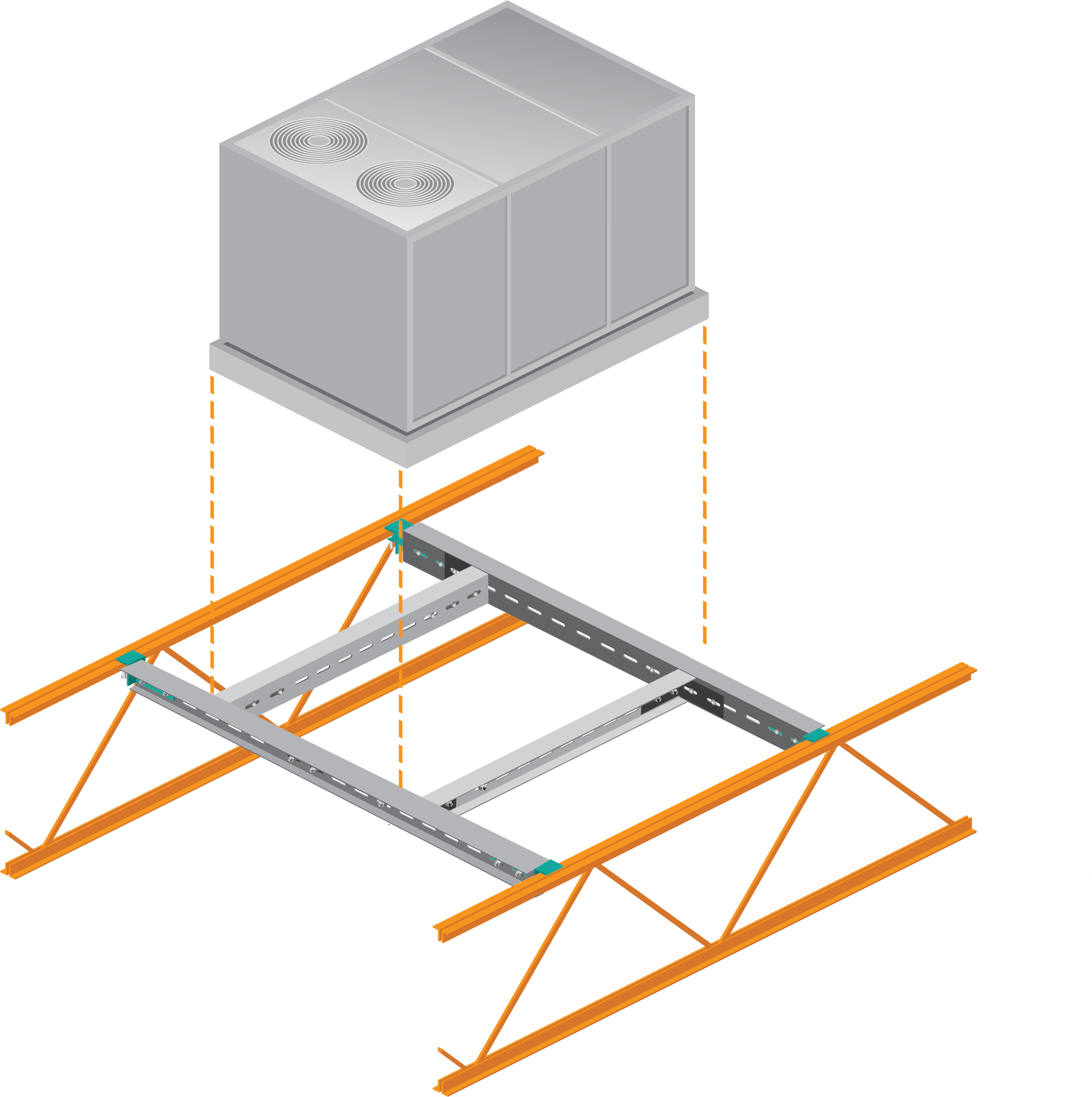

BOLT-IN ROOF FRAMES

Bolt-in QuickFrames are made from galvanized steel and are adjustable with telescoping rails that bolt into a structure from under the roof decking, requiring no welding, making them a good solution for remodel and tenant improvement projects.

- Reduce rework

- Easy to install

- No weld required

-

Ship fully assembled

-

Adjustable in the field

-

Can be detached and moved

Drop-IN ROOF FRAMES

Fully assembled, weldable, drop-in roof frames are a great option to using angle iron for new construction projects where the decking hasn’t been installed as they can be adjusted in the field, are reuseable, and built to your shop drawings.

Get Your Engineering Submittal for Approval

We will help you keep your project moving forward by providing site specific engineering for QuickFrames roof frames. Our engineers will review your plans and provide sealed calculations and shop drawings to meet your project needs.

QuickFrames works with a nationally recognized engineering firm who holds licenses in all 50 states so that we can provide engineering guidance to our customers working on projects across the U.S. and Canada while ensuring the highest level of integrity.

Roof Frames that Deliver

INSTALLED BY INDUSTRY PROFESSIONALS

QuickFrames can be found across the United States and Canada in installations from battery plants, distribution centers, retail stores, educational institutions, medical facilities, restaurants, and more, and are used by top-notch builders and companies.

Testimonials

What our customers say

Use Cases & Industries

See how you can achieve the structural support and efficiency QuickFrames provide and find out how QuickFrames are used across the industries we serve.